EPSCement®

Användningsområden

EPSCement® kan användas för alla typer av golvkonstruktioner, där ytor behöver fyllas upp till färdiga golv. Efter beläggning med avjämning/slipsats ger EPSCement® golvytor starka nog att beläggas med matta, klinker, parkett etc.

Andra användningsområden är t.ex. platta på mark, parkeringsdäck, värmeisolerande yttertak med falluppbyggnad och väggputs inomhus/utomhus, uteplats, trädgårdsgång, vindsvåning, pool, flytbrygga, garageuppfart, lagning av vattenskada m.m.

Översikt Villa

Ljuddämpande badrum för högre levnadsstandard

EPSCement® används med fördel för uppgjutning av badrumsgolv. EPSCement® tillför låg vikt och skapar en solid fuktsäker golvkonstruktion speciellt lämpad för tätskiktsystem med keramiska plattor.

Torktiden är kort och bygget tillförs ingen fukt tack vare de självuttorkande egenskaperna. EPSCement® innehåller inget organiskt material och kan därmed inte mögla. Med betong och isolering i samma material blir det mycket mindre energiförluster. EPSCement® kan både gjutas på golv och sprutas på vägg.

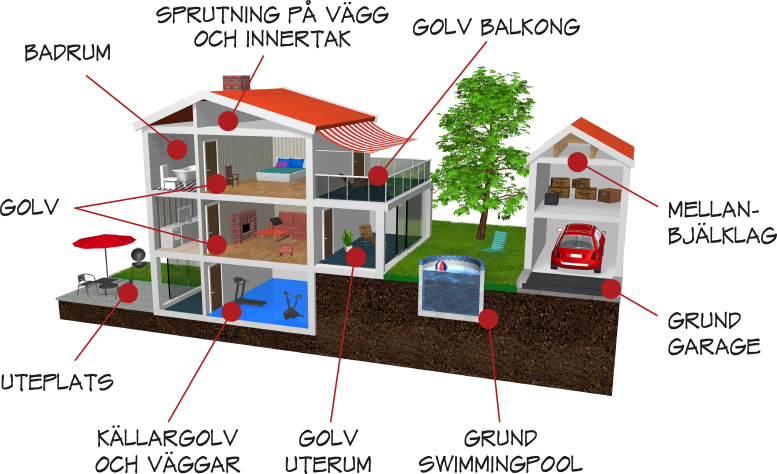

VÄGG OCH BADRUMSGOLV PÅ BETONG

VÄGG: 1. Befintlig vägg betong/sten, 2. Primer, 3. EPSCement®, 4. Väggspackel, 5. Tätskikt, 6. Fästmassa, 7. Kakel

GOLV: 1. Betong, 2. Plastfolie*/primer, ej åldersbeständig, 3. EPSCement®, 4. Avloppsrör, 5. Varm- och kallvattenrör, 6. Rotnät/Tensobar, 7. Golvvärme ingjuten i flytspackel, 8. Flytspackel, 9. Tätskikt, 10. Fästmassa, 11. Klinke

*Plastfolie, ej åldersbeständig – Endast om ni vill ha en flytande konstruktion.

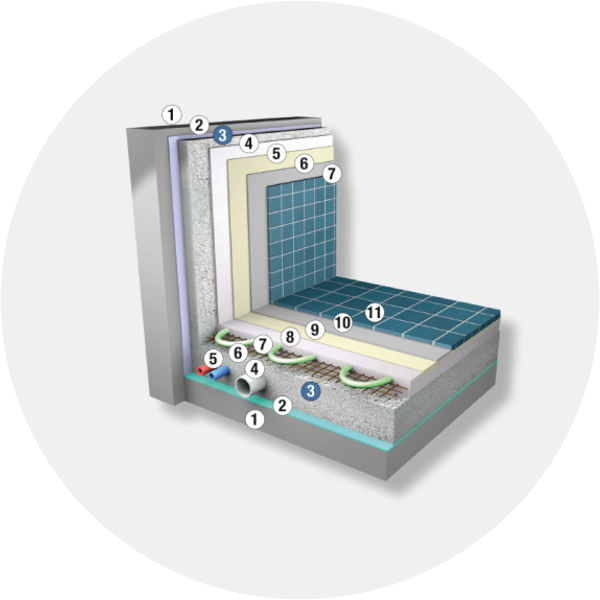

VÄGG OCH BADRUMSGOLV PÅ TRÄBJÄLKLAG

VÄGG: 1. Befintlig vägg betong/sten, 2. Primer, 3. EPSCement®, 4. Väggspackel, 5. Tätskikt, 6. Fästmassa, 7. Kakel

GOLV: 1. Undertak, 2. Glespanel, 3. Regel, 4. Trossbotten, 5. Träbjälklag 45 x 220 mm, 6. Plastfolie*, 7. EPSCement®, 8. Rotnät/Tensobar, 9. Golvvärme ingjuten i flytspackel, 10. Flytspackel, 11. Tätskikt, 12. Fästmassa, 13. Klinker

*Plastfolie, ej åldersbeständig – Vi behöver plasten endast för att säkerställa att alla vattendroppar blir kvar vid läggningen, till den snabba härdningsprocessen.

Isolerande golv på mark med EPSCement® (t.ex. källargolv)

Vid gjutning av nytt betonggolv eller byte av gammalt, gjuter man med fördel med EPSCement®. Eftersom EPSCement® är diffusionsöppen och kan andas kan konstruktionen ta hand om eventuell tillskjutande fukt.

Torktiden är kort och bygget tillförs ingen fukt tack vare de självuttorkande egenskaperna. EPSCement® innehåller inget organiskt material och kan därmed inte mögla. Med betong och isolering i samma material blir det mycket mindre energiförluster. Om du sedan belägger EPSCement® med golvvärme värmer du endast spackel lagret och inte hela plattan som med vanlig betong.

RENOVERINGSGOLV PÅ MARK

1. Makadam - kapillärbrytande skikt, 2. Markduk, 3. EPSCement®, 4. Avloppsrör, 5. Varm- och kallvattenrör, 6. Rotnät/Tensobar, 7. Golvvärme ingjuten i flytspackel, 8. Flytspackel minst 20mm

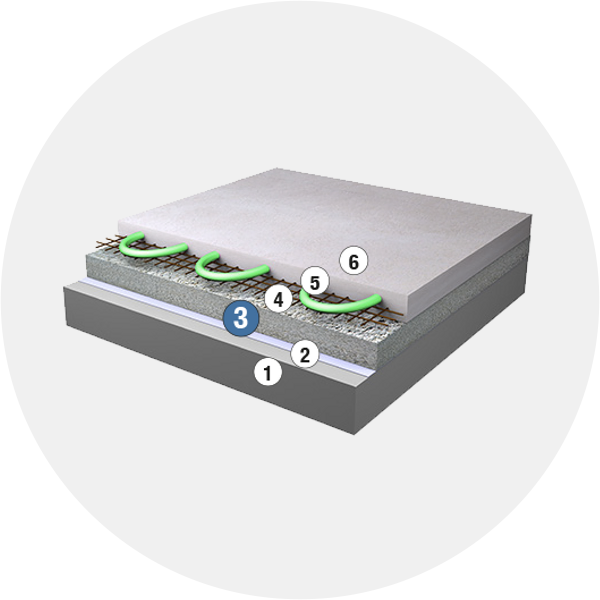

Isolerande & ljuddämpande golv på betongplatta

Torktiden är kort och bygget tillförs ingen fukt tack vare de självuttorkande egenskaperna. EPSCement® innehåller inget organiskt material och kan därmed inte mögla.

Med betong och isolering i samma material blir det mycket mindre energiförluster. Om du sedan belägger EPSCement® med golvvärme värmer du endast spackel lagret och inte hela plattan som med vanlig betong.

GOLV PÅ BETONGPLATTA

1. Betongplatta, 2. Plastfolie*/Primer, 3. EPSCement®, 4. Rotnät/Tensobar, 5. Golvvärme, 6. Spackel

*Plastfolie, ej åldersbeständig – Endast om ni vill ha en flytande konstruktion.

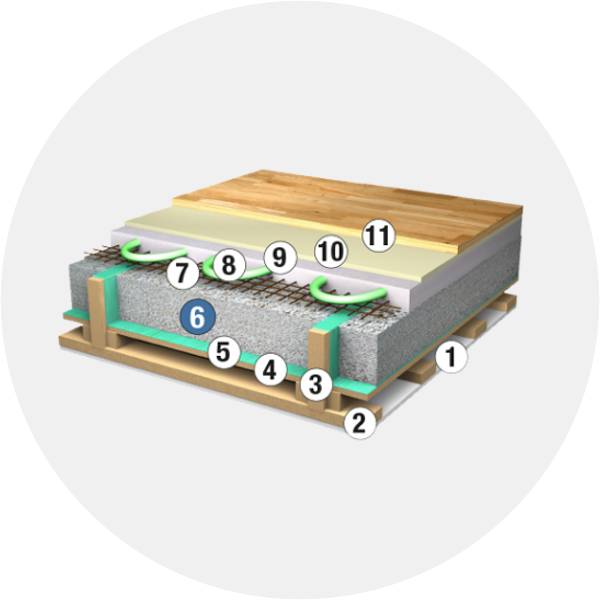

Isolerande & ljuddämpande golv på träbjälklag

Med EPSCement® i träbjälklag skapar du säkra golv med stabilitet likt ett betonggolv men med låg vikt och utan fördröjande torktider och med miniminerad risk för vattenskador.

Här spar man även bygghöjd då EPSCement® läggs till överkant regel och sedan spackel inga ”plushöjder”.

GOLV PÅ TRÄBJÄLKLAG

1. Undertak, 2. Glespanel, 3. Regel, 4. Trossbotten, 5. Plastfolie, ej ålderbeständig, 6. EPSCement®, 7. Rotnät/Tensobar, 8. Golvvärme, 9. Flytspackel, 10. Tätskikt, 11. Parkett

Golv på betongbjälklag med ingjutna installationer

Vid befintligt bjälklag som ska gjutas in i olika installationer - Gjut på med den tjocklek som behövs men min. 30mm EPSCement® och min. 15mm spackel.

Med EPSCement® får man ett stegljudsdämpande skikt till underliggande ytor.

GOLV PÅ BETONGBJÄLKLAG

1. Betongbjälklag, 2. Plast - ej åldersbeständig, 3. EPSCement®, 4. Ventilation ingjuten, 5. Avlopp ingjutet, 6. Varm- och kallvattenrör, 7. El ingjuten, 8. Fiberkabel ingjuten, 9. Rotnät/Tensobar, 10. Golvvärme, 11. Spackel

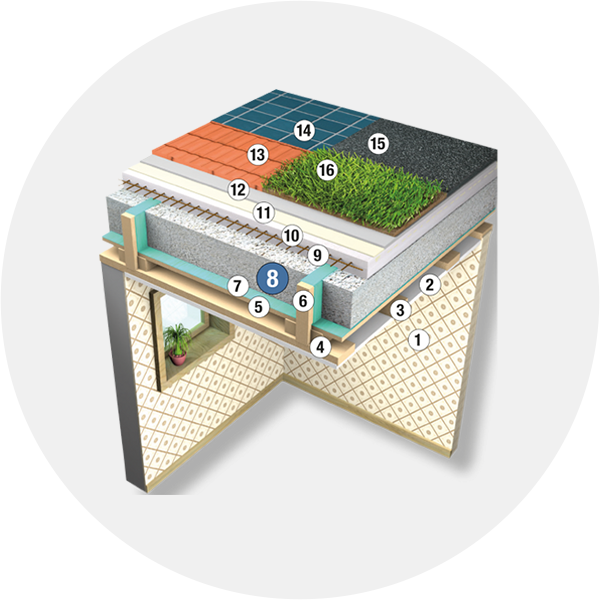

EPSCement® vid takbjälklag

Här blir konstruktionen lika i utförande som träbjälklag men kan även gjutas på konstruktionsplåt. Denna konstruktion kan användas då man vill bygga på ett garage/utbyggnad till ett skönt uterum eller utöka bostaden.

Då materialet har brandklass A2 som är obrännbart medför det även ett brandskydd.

EPSCEMENT® VID TAKBJÄLKLAG

1. Vägg, 2. Undertak, 3. Glespanel, 4. Regel, 5. Trossbotten, 6. Träbjälklag 45 x 220 mm, 7. Plastfolie*, 8. EPSCement®, 9. Rotnät/Tensobar, 10. Flytspackel, 11. Tätskikt, 12. Eventuell fästmassa beroende på ytskikt, 13. Klinker, 14. Takpannor, 15. Asfalt/takpapp, 16. Sedumtak (grästak)

*Plastfolie, ej åldersbeständig – Vi behöver plasten endast för att säkerställa att alla vattendroppar blir kvar vid läggningen, till den snabba härdningsprocessen.

Isolerande grund / platta

Snabba och isolerande grunder helt utan energislukande köldbryggor. Med denna lösning slipper man långa väntetider för att gjutningen skall kunna beläggas.

Redan efter 12 timmar kan man lägga armering- / rotnät och spackel. Belägg golv enligt spackeltillverkarens rekommendation.

GRUND

1. Makadam - kapillärbrytande skikt, 2. Markduk, 3.Kantelement, 4. EPSCement®, 5. Rotnät/Tensobar, 6. Golvvärme ingjuten i flytspackel, 7. Flytspackel minst 20mm

Isolerande gårdsbjälklag

Mindre vikt på befintlig konstruktion samt bättre isolering. Kan överläggas efter 12 timmar.

Med isoleringen som finns inbyggt i materialet kan du med fördel lägga en värmeslinga för att bekämpa halkrisk vintertid samt att det tinar då vårsolen tittar fram.

Varför välja EPSCement®?

Tunga skäl som talar för en lättare betong!

- Lätt

- Hållfast

- Diffusionsöppen

- Pumpbar

- Fukt- & Frostsäker

- Isolerande

- Ljuddämpande

- Brandskyddande

- Sprutbar

- m.m.